The construction environment in Bangalore has been developing fast over the last decade. Modern fabrication technologies have never been used in the industry like today, as changing needs in the city, safety demands, and the need to deliver projects faster have necessitated modern fabrication technologies. Today, sophisticated creation is no longer a bonus but a requirement in the provision of quality and durable buildings in an ever-increasing urban centre.

Since the meticulously made slab reinforcement to the high standard of steel elements, fabrication has emerged as one of the key pillars of companies that were determined to become the best construction company in Bangalore. This is an elaborate guide as it highlights the uses of fabrication in supporting the entire slab design to structural stability, as well as outlining the necessary engineering terms, such as a distinction between one and two-way slabs.

How Advanced Fabrication Is Transforming Building Construction in Bangalore

The need to have efficient, safe and durable structures has promoted the use of fabrication technologies in large numbers. The role of fabrication in the building constructions of Bangalore, in regard to the speed, precision and cost control, is significant. Beams, columns, steel framework, slab reinforcements, among others, can be produced in an off-site location and brought to the construction site to minimise on-time and man-hours.

The contemporary fabrication minimises wastage, enhances the precision of measurements, and improves stability, which are three aspects that have a significant impact on the performance of a building throughout its existence. These are the abilities that make the firms stand out as the best construction firm in Bangalore, through the provision of structural quality uniformity.

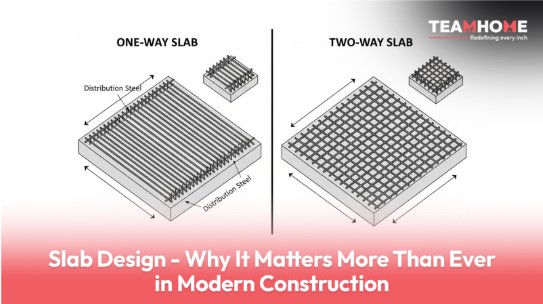

Slab Design—Why It Matters More Than Ever in Modern Construction

Slabs are considered to be one of the most significant structural elements of a building. They create roofs and floors and support loads, and evenly distribute the weight. Slab design needs to be accurate and very strong with the increasing vertical developments of Bangalore.

Fabrication also plays an important role in accelerating the slab reinforcement. Ready-made steel nets and supports ensure that every slab will not collapse under the load suddenly. This is particularly important when the construction schedule is tight, as in the case of building construction in Bangalore.

One of the concepts a homeowner, construction enthusiast or any engineer ought to grasp is the difference between one and two way slab. The difference affects the material used as well as fabrication methods, structural performance and cost.

Understanding the Difference Between One and Two Way Slab

To simplify:

One-Way Slab

- A slab is said to be one-way if it bends in only one direction.

- Two parallel beams were used to support the same.

- One-way only transfer of load.

- Less support is needed in the second direction.

Two-Way Slab

A two-way slab is bent in two directions.

- Supported on all four sides.

- Distributed load in two directions.

- Needs to be reinforced in balance on both sides.

Fabrication also makes sure that the steel reinforcement of both types of slabs is cut, bent, and positioned in a manner most favourable to the distribution of loads. Knowledge of the one-way slab and the two-way slab also makes the clients query and confirm whether the adopted methodology is suitable for their type of construction, which is a major factor in choosing the best construction firm in Bangalore.

The Role of Fabrication in Enhancing Structural Integrity

The structural integrity explains the duration of the lifespan of the structure and the safety in which the structure will be executed. The weather conditions of Bangalore, the soil differences and the necessity of the earthquake resistance design make the high-quality fabrication even more significant.

In the case of modern fabrication, the effects are influential on the structural integrity in the following ways:

Precision and Consistency in Material Strength

False parts are subject to quality inspection in the course of production. Contrary to manual work onsite, conditions in the factories guarantee:

- uniform steel strength,

- accurate dimensioning,

- controlled bending radius,

- proper weld quality.

This continuity is a key to any firm that wishes to be the number-one construction firm in Bangalore.

Reduced On-Site Errors

Errors in cutting, welding, or centering of the steel parts bring structural weakness. Ready-to-use building blocks minimise such errors to a minimal extent, which contributes to the building construction that is more reliable in Bangalore.

Improved Load Distribution in Slabs

Made reinforcement provides the proper space and location of the steel rebars, which makes it easier to design slabs, particularly when the difference between the one-way slab and the two-way slab needs to be taken into account and hence reinforced accordingly.

How Fabrication Drives Faster Project Delivery in Bangalore

Fabrication is another method of quickening construction in a city where project completion is done within very strict deadlines, as this facilitates simultaneous workflows. This is done at the same time that steel slabs and column components are being made on-site as the foundation is being prepared.

Reduced Labour Dependency

Fabrication reduces the use of huge labour groups on the ground, which is necessary during high seasons of building construction in Bangalore.

Time-Saving Installation

Slab reinforcement and structural assembly is fast because elements are ready to be put in place. This would be of great advantage to multi-storey developments where slab cycles should be quick and predictable.

Lower Material Wastage

State-of-the-art fabrication methods are tailor-made to cut efficiency, saving a lot on steel wastage. The best construction company in Bangalore is becoming sustainable.

Choosing the Best Construction Company in Bangalore—Why Fabrication Should Be a Key Factor

Not every construction company spends money on sophisticated fabrication technologies. Homeowners and developers must take an active interest in determining, when selecting the best construction company in Bangalore, whether the given company employs:

- pre-fabricated slab reinforcement,

- advanced steel cutting and bending machines,

- factory-tested structural components,

- slab analysis tools that consider the difference between one and two way slab.

These aspects have a significant impact not only on the speed of construction but also on the safety and life cycle of the structure.

This is because those companies that embrace the most superior fabrication are in a better position to provide high-quality building construction in Bangalore with very few defects and durability.

Conclusion

The paradigm shift to high fabrication in the construction industry has changed the way buildings are constructed and designed in Bangalore. Fabrication brings accuracy, speed and safety at each level of slab reinforcement to structural assembly. The distinction between a one-way slab and a two-way slab also illustrates the importance of being precise in contemporary building construction.

Fabrication should be a major decision-making factor for those who are looking to hire the best construction company in Bangalore, whether at home or in the hands of developers. It not only improves the building construction quality in Bangalore but also provides long-term structure integrity.